Thermoplastic Shoe Pad Factory Custom Made Heat Moldable Insoles

Specifications

| Item | Thermoplastic Shoe Pad Factory Custom Made Heat Moldable Insoles |

| Material | Surface: BK mesh Body: EVA Inner Shell: PETG plastic material |

| Size | 30, 32, 34, 36,38,40, 42, 44, 46, 48,50 or customized |

| Color | Black or any Pantone number customized |

| Density | can be customized |

| Logo | Customized Logo can be on mould or printed on topcover |

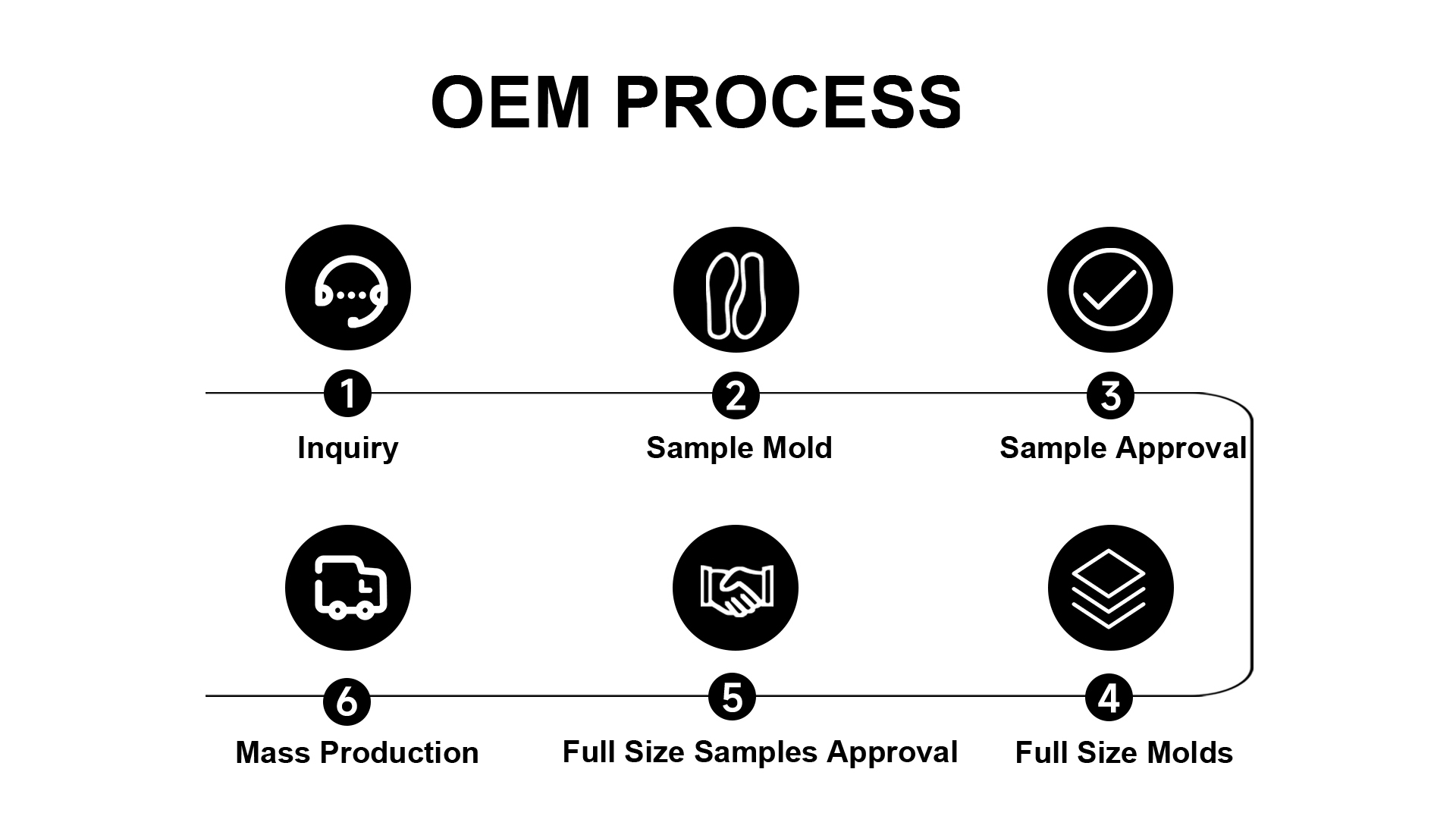

| OEM&ODM | Customized designs based on your sample or 3d drawing |

| MOQ | 1000 pairs |

| Payment Term | By T/T, 30% deposit and 70% balance before shipment |

| Lead Time | 25-30 days after payment and sample confirmed |

| Package | Usually 1 pair/plastic bag, welcome customized packaging |

| Delivery | DHL/FedEx etc for sample/small order; Sea/Train for large quantity |

Features

- 1. Oven Insole mold to the shape of your foot

- 2. Adjustable Arch Support and heel cup

- 3. Offers a personalized, custom fit and genuine comfort all day

- 4. Relieves pain & soreness from flat feet, bunions, back and knee pain, and plantar fasciitis

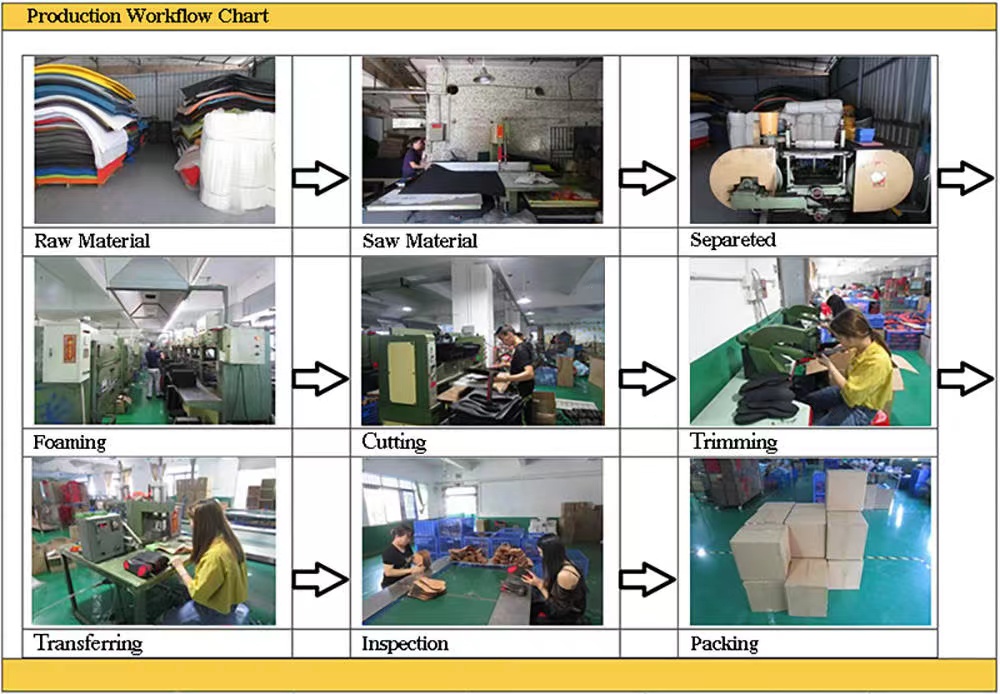

Production Process

Heating Method Options

1) Wear Mold Instructions-- Place the oven Insole into your footwear and wear same as any other shoe insole. Your body heat will mold the orthotic to your foot after a few days.

2) Heat Mold Instructions-- Preheat Conventional Oven to 200°F or Convection Oven at 175°F. Place orthotics in oven for 3 minutes. Remove orthotics from oven and immediately place into your footwear. Ensure they are sitting flat in your shoes (wrinkle-free) and stand up straight in your shoes with toes pointed forward and your feet shoulder-width apart for 1-2 minutes.

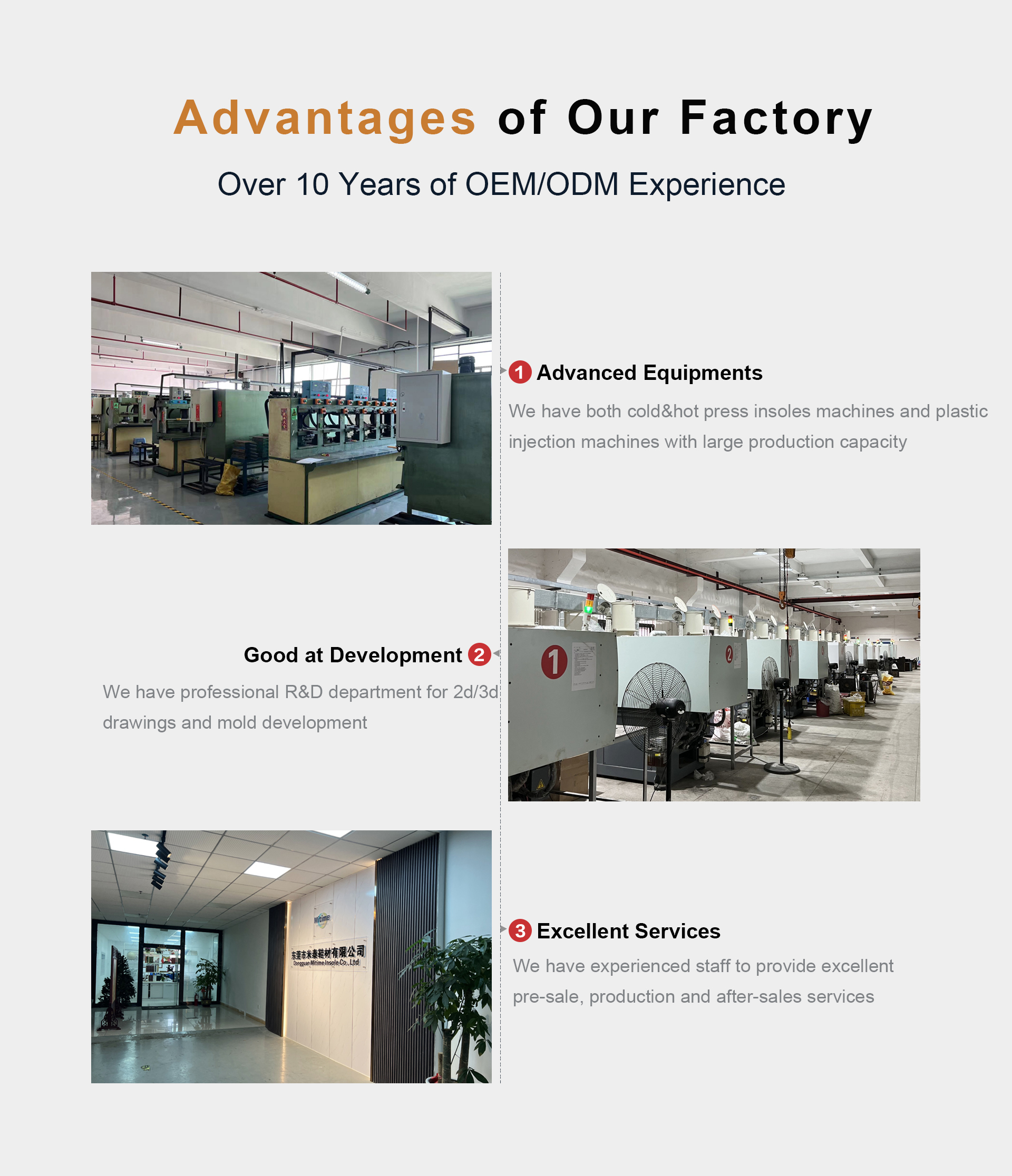

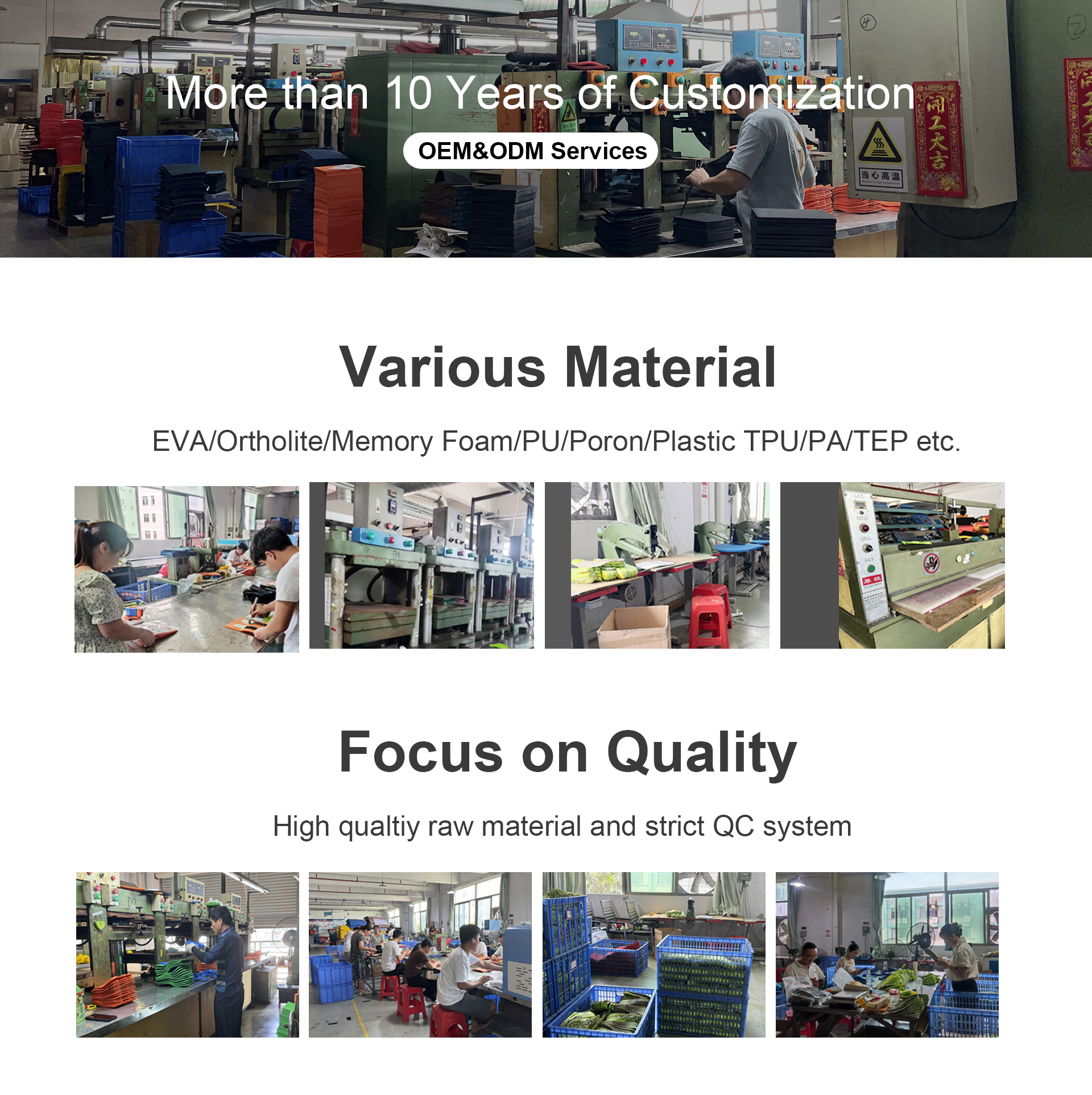

About Our Factory

Write your message here and send it to us